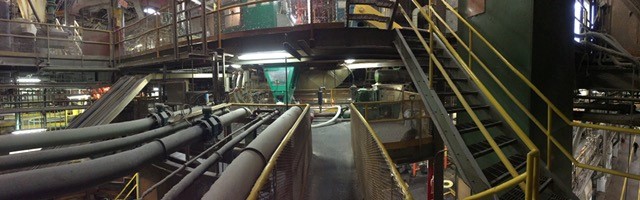

Edge Trim Hopper

ZAP completed the engineering for the replacement of the client’s edge trim re-feed hopper, blowers, and transport lines at their facility. ZAP’s design included an increase to five outputs metered using blow-through rotary valves, continuous hopper level monitoring using a laser distance sensor, five individual positive displacement blowers, the design of a new monorail to lift and move the blowers, and reduced transport line size to increase transport velocity and reduce line plugging. ZAP was able to meet all client requirements and was available to the client for questions and clarifications during fabrication and installation activities.