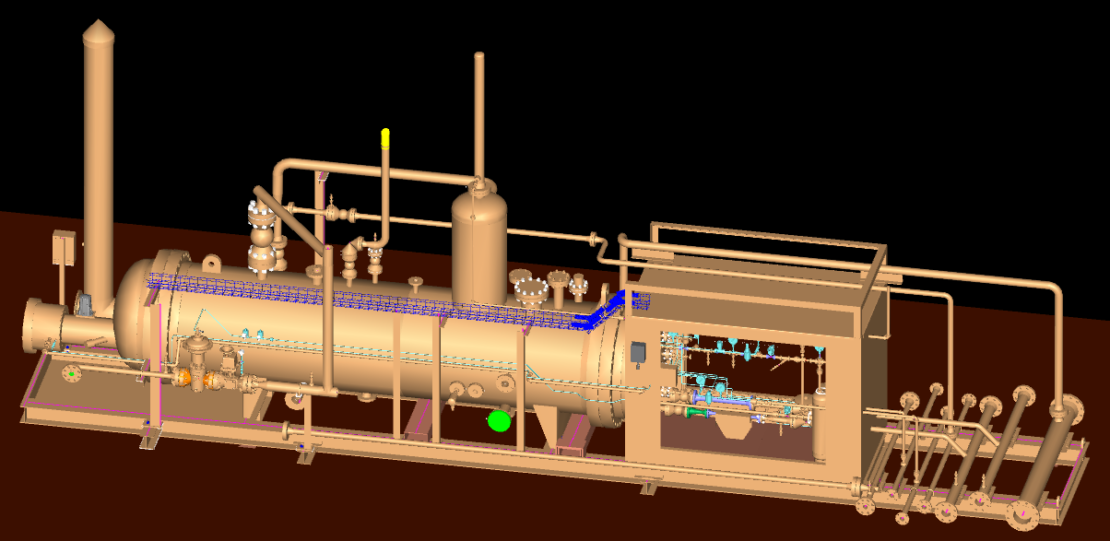

Three-Phase Separator Skid Detail Design

ZAP produced detailed engineering documentation, 3D models and component fabrication drawings for a client that wanted to create and own the separator design. During the package creation process, design drawings and models were provided to the client to review and provide their feedback, resulting in the client being able to leverage their lessons learned and best practices into their custom design. The design package was used to request quotes from several skid packagers with the knowledge that skids produced by different manufacturers would all have the same internal design as well as external interface dimensions.

These separators have been utilized at over 70 of the client’s wellhead production facilities gathering and processing production from over 400 new horizontal wells. The separator skids have now been produced by seven different manufacturers. Detailed vessel design packages included the structural, mechanical, electrical, and control deliverables necessary for manufacturing of the separator skids. With the new separator design, the client was able to transition to an above ground/modular wellhead production facility reducing the construction time by more than 50 percent with mechanical construction which resulted in less than one week per site.