Midstream Oil & Gas

40 MMSCFD Powder River Basin BOP Engineering ZAP provided engineering and design for the construction of a 40 MMSCFD Gas Plant in Converse County, WY. The plant was designed for future capacity expansion to 100 MMSCFD. The plant design includes fingers inlet liquid storage, 12 RVP stabilizer, a refrigerated J-T gas processing unit, fractionation unit, […]

Upstream Oil & Gas

ZAP worked with a client to produce engineering documentation and design for over 170 wellhead production facilities gathering and processing production from over 1,000 new horizontal wells, including: all mechanical, civil, electrical, and control deliverables necessary for construction and facility documentation records.

Midstream Oil & Gas

ZAP provided engineering, design, procurement management, and construction support for a 20 MMSCFD greenfield gas processing facility in North Dakota including:

Midstream Oil & Gas

ZAP provided turnkey engineering and procurement services for the engineering phase of this project and subsequently served as the general contractor for the construction phase.

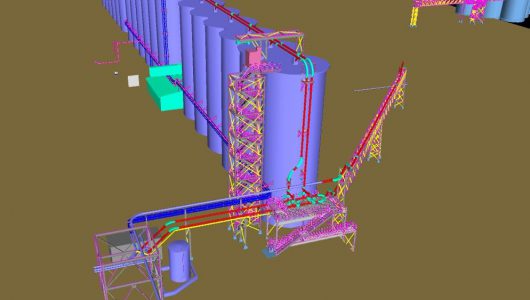

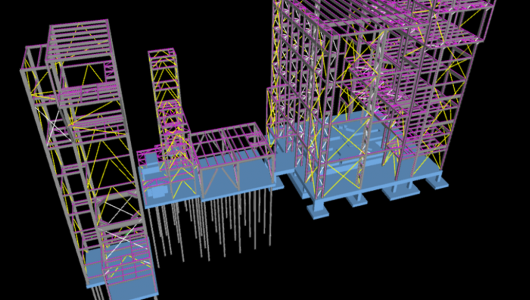

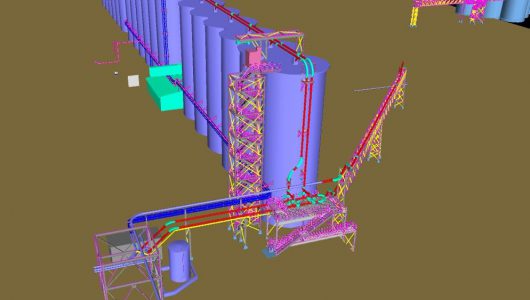

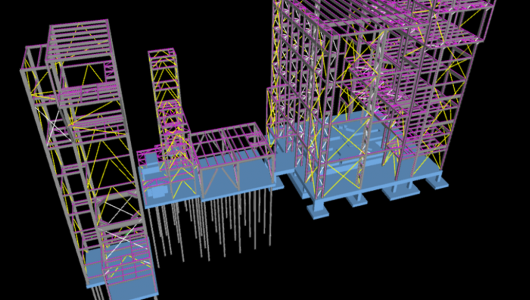

Cement, Mining, and Minerals

Distribution Terminals

ZAP provided preliminary engineering and design for a cement and granulated blast furnace slag import and distribution terminal.

Midstream Oil & Gas

ZAP provided engineering, design, and procurement management for a 10 MMSCFD greenfield cryogenic gas processing facility.

Midstream Oil & Gas

ZAP provided turnkey engineering and procurement services for the engineering phase of this project and subsequently served as the general contractor for the construction phase.

Midstream Oil & Gas

ZAP provided engineering, design, and construction management for several optimization, addition, and refurbishment projects at a 64 MMSCFD brownfield gas processing facility.

Cement, Mining, and Minerals

ZAP provided engineering and detailed design for a pneumatic conveying system upgrade and conveying line reroute.

Midstream Oil & Gas

ZAP provided engineering, design, and procurement management for a 50 MMSCFD greenfield gas processing facility.

Cement, Mining, and Minerals

ZAP provided preliminary engineering and design for a vertical cement mill grinding system.

Midstream Oil & Gas

ZAP provided turn key engineering, design, and construction for a green field project consisting of two separate compressor sites.

Midstream Oil & Gas

ZAP provided engineering and design on a brownfield site.

Midstream Oil & Gas

To help our client meet product specification and station uptime requirements at a 50 year old 60MMSCFD gas fractionation plant, ZAP engineered a solution to replace the controls system while drastically minimizing production outages during the upgrade.