Cement Distribution Terminal

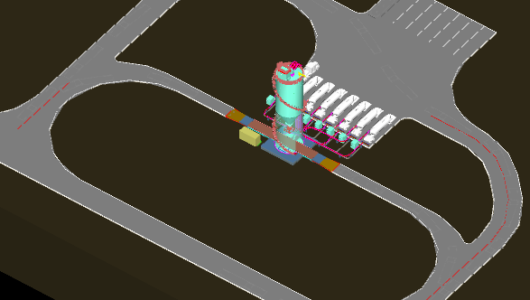

ZAP was contracted to perform conceptual layout, design and total installed cost estimate for a new pneumatic truck off-loading, storage and automated truck loading system.

ZAP has executed over a 1,000 projects since 2001. Ensuring the success of your project is our primary objective.

ZAP was contracted to perform conceptual layout, design and total installed cost estimate for a new pneumatic truck off-loading, storage and automated truck loading system.

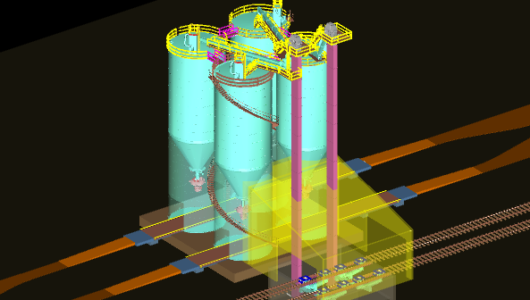

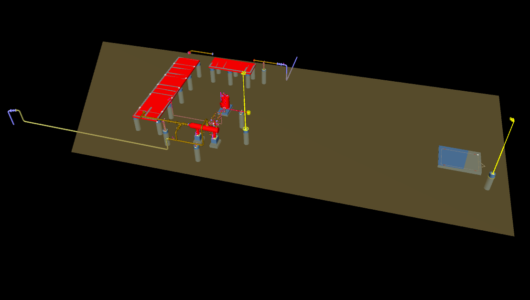

ZAP was contracted by our client to perform conceptual layout and design for a new rail distribution terminal. The system was designed to receive cement by dual rail tracks and off-load simultaneously into one of four silos.

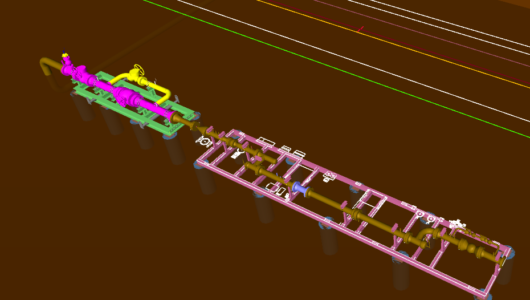

Pig Launcher Modifications, Regulator Install, and IA Addition ZAP Engineering completed design work on modifying the piping of an existing pig launcher to accommodate the addition of a regulator skid, and instrument air building at a site located in the pipeline ROW.

Meter Skid and Pig Valve Skid Installation ZAP Engineering completed design work for the installation of a new meter skid and pig valve skid at a third party site.

Filter, Meter Skid and Control Valve Skid Installation ZAP Engineering completed design work for the installation of a new filter coalescer, meter skid, and control valve skid at a third party interconnect site. Scope included specifying the equipment, and preparing a complete construction drawing package.

Preheater Evaluation A cement plant was seeking to upgrade the size of the cyclones in their Preheater Tower which was going to modify both the framing geometry and maximum expected gravity and seismic loads on the tower. A structural & construction evaluation was required to provide a total installed cost and schedule estimates for their […]

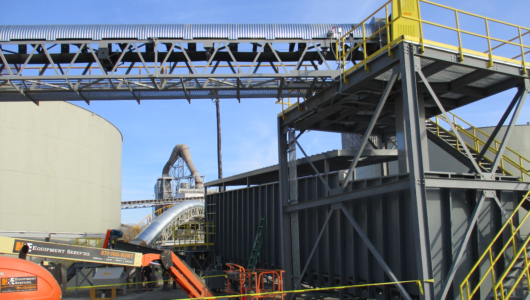

TDF Electrical and Instrumentation A cement plant improving the efficiency of their alternate fuel sources requested that ZAP provide electrical and instrumentation design to support the integration of equipment packages into a single material handling system. The new system would allow for the delivery of whole tires that would be shredded prior to being used […]

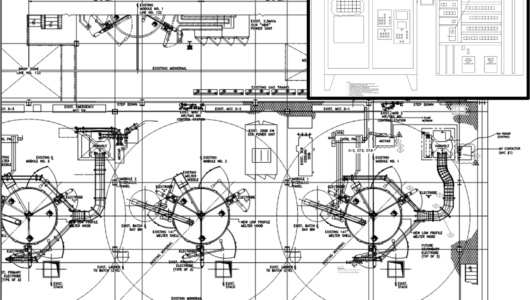

Power Supply Replacement ZAP replaced one of three existing power supplies serving the three glass melters. The existing 1.8MW power supply was replaced with a new 3MW variable voltage transformer and a new MV vacuum contactor and disconnect switch was installed to feed the new transformer. ZAP evaluated the existing steel structure for the installation […]

Outside Hopper Structural Support ZAP developed an engineered repair plan with a repair sketch for a self-supporting Lime Hopper which was struck by a moving vehicle and sustained substantial damage to a column, vertical bracing, anchor bolts, etc. ZAP completed a site visit to determine the extent of the damage and complete the repair sketch.

Monorail Update ZAP provided structural engineering and design to support the client in their effort to provide a turn-key solution for a monorails installed in a hazardous reagent building located on a gold concentrate facility in Colorado. ZAP completed a site visit to visualize each of the spaces and confirm the end-user’s intent and as-built […]

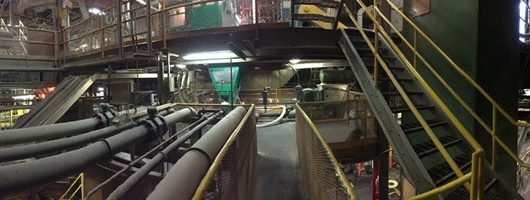

Edge Trim Hopper ZAP completed the engineering for the replacement of the client’s edge trim re-feed hopper, blowers, and transport lines at their facility. ZAP’s design included an increase to five outputs metered using blow-through rotary valves, continuous hopper level monitoring using a laser distance sensor, five individual positive displacement blowers, the design of a […]

Relocated Silo, Foundation Design, and Permit Support: ZAP performed NFPA study to determine the appropriate location of the relocated silo with respect to the deflagration vents located on it and an existing adjacent silo.

Monorail Addition at Roof A manufacturing customer wanted to add a new monorail and increase the capacity of existing monorails supported by the building roof trusses above their process equipment. ZAP provided analysis of the existing trusses, which had already been reinforced when monorails were first added. The customer requested modifications to our design based on […]

ZAP was contracted by the cryogenic plant equipment packager to engineer and design the installation of a greenfield cryogenic gas plant in the Permian Basin.

Excellence in Execution

ZAP is excited to announce the launch our expansion into the Eastern US with the addition of our East Coast Engineering office in Bethlehem, PA!

ZAP is excited to announce the launch our expansion into Houston, TX! We are thrilled to welcome Chris Combs who will assume the role of Vice President – Gulf Coast Engineering!